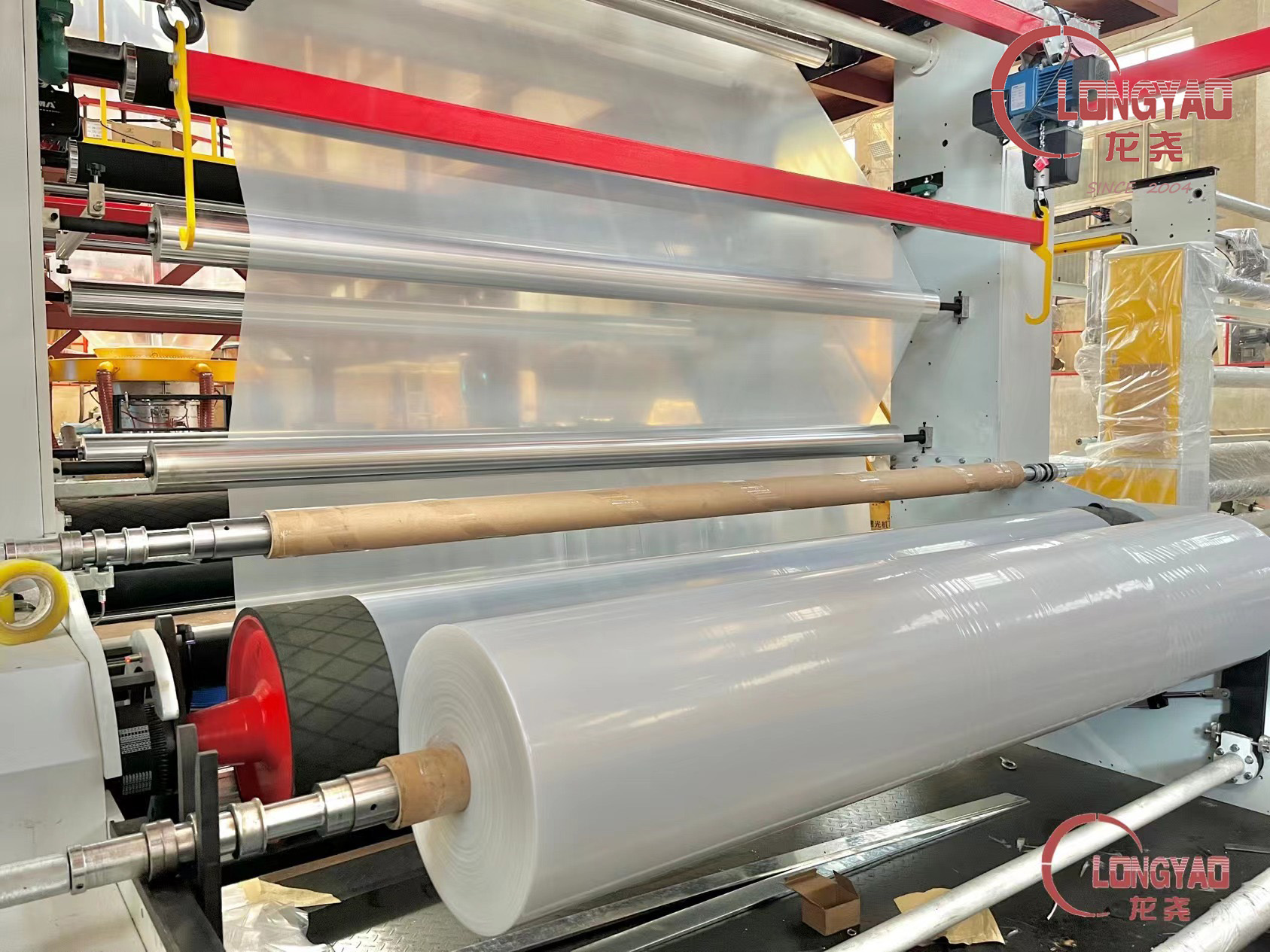

ABA PE Heat Shrink Film Blowing Machine

Features

1.Air ring: The Aba PE Heat Shrink Film Blowing Machine has an air ring that provides a uniform cooling effect on the film as it is being produced. This ensures the film maintains its shape and prevents deformation.

2. Bubble cage: The PE Shrinkable Film Blowing Machine has a bubble cage that helps to create the bubble in the film as it is being produced.

3.Collapsing frame: The machine has a collapsing frame that allows the bubble to be collapsed into a flat film that can be wound into a roll.

4.Tension control: The machine is equipped with a tension control system that ensures the film is produced at a consistent tension level. This helps to prevent any issues with the quality of the final product.

Product Description

1. there is a direct relationship between the film quality of heat shrinkable film and the production Aba PE Heat Shrink Film Blowing Machine used to manufacture it. The quality of the film can be influenced by a number of factors, including the raw materials used, the manufacturing process, and the equipment used to produce the film.

2. The production Shrink Film Blowing Machine used to manufacture heat shrinkable film can directly impact the quality of the film. For example, if the equipment used is outdated, poorly maintained, or not properly calibrated, it can lead to inconsistencies in the thickness or clarity of the film. In addition, if the equipment is not designed to handle certain types of materials or production speeds, it can result in defects such as pinholes or weak spots in the film.

3. On the other hand, modern, high-quality production equipment that is properly maintained and calibrated can produce heat shrinkable film that is more consistent in terms of thickness, clarity, and strength. This can result in a better overall quality of the film and more consistent performance during the shrink-wrapping process.

Product detail