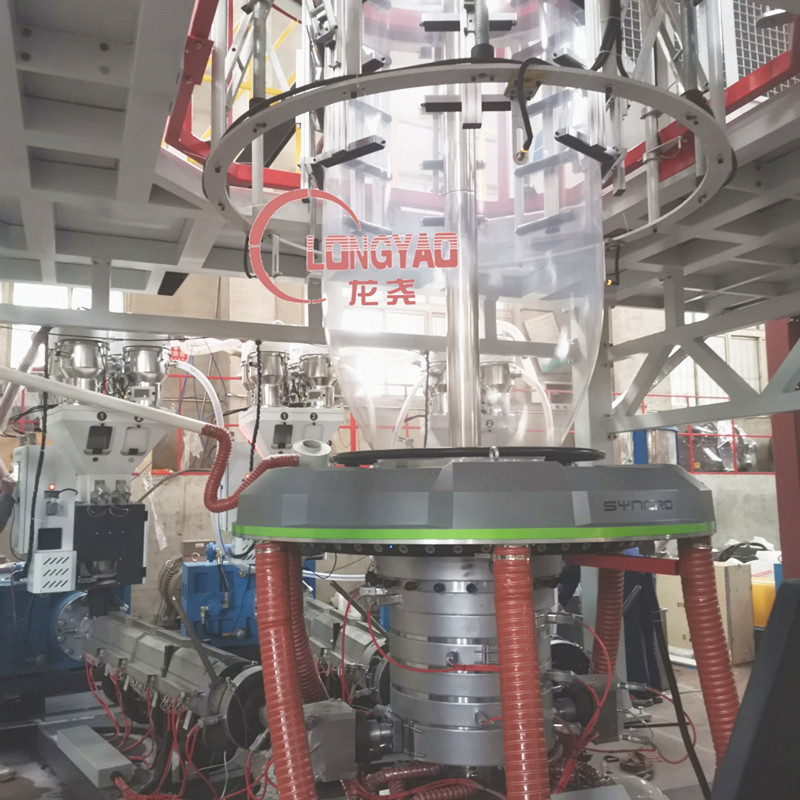

Dalian Longyao Plastic Machinery Co., Ltd.'s three-layer co-extrusion blown film machine equipment specifications range from 1200-3200mm, which is a popular specification, with upper traction rotation, internal cooling, four-component Dosing system, automatic winding and cooling fan. These are our commonly used configuration methods. The film quality is good, the winding is neat, and the machine is stable in production, which is well recognized by customers.

3 layer blown film extrusion machine offer several advantages compared to other types of blown film machines. Here are some key benefits:

Versatility: The three-layer co-extrusion blown film machine allows you to produce films with three distinct layers, each having different properties. This versatility enables you to create films with varying thicknesses, materials, and barrier properties, making it suitable for a wide range of applications such as packaging, agriculture, construction, and more.

Enhanced Barrier Properties: With the ability to incorporate different materials in each layer, three-layer co-extrusion blown film machines can create films with improved barrier properties. For example, you can have a central layer with a barrier material like EVOH (ethylene vinyl alcohol) to provide excellent gas barrier properties, while the outer layers can have different characteristics like strength, flexibility, or printability.

Cost-effectiveness: By utilizing multiple layers, three-layer co-extrusion blown film machines allow for better material utilization and cost savings. You can use lower-cost materials for the outer layers while using a smaller amount of expensive materials for the inner layer with specific performance requirements. This helps optimize material usage and reduce production costs.

Optimal Film Performance: The ability to control the thickness and properties of each layer independently enables the production of films with precise performance characteristics. You can tailor the film's mechanical properties, such as tensile strength, puncture resistance, and tear resistance, as well as optical properties like transparency and gloss, to meet specific application requirements.

Product Differentiation: With three-layer co-extrusion blown film machines, you can create films with unique combinations of properties, leading to product differentiation in the market. By offering films with improved barrier performance, enhanced strength, or specialized functionalities, you can cater to specific customer needs and gain a competitive edge.

Energy Efficiency: Co-extrusion blown film machines are generally more energy-efficient compared to other types of film extrusion processes. By optimizing the design and incorporating advanced technologies, three-layer co-extrusion machines can minimize energy consumption, reduce waste, and improve overall production efficiency.

The advantages of ABC Industrial packaging film blowing machine lie in their versatility, cost-effectiveness, enhanced barrier properties, film performance optimization, product differentiation, and energy efficiency. These machines enable you to produce high-quality films with customized properties, expanding your product capabilities and meeting the diverse demands of the market.