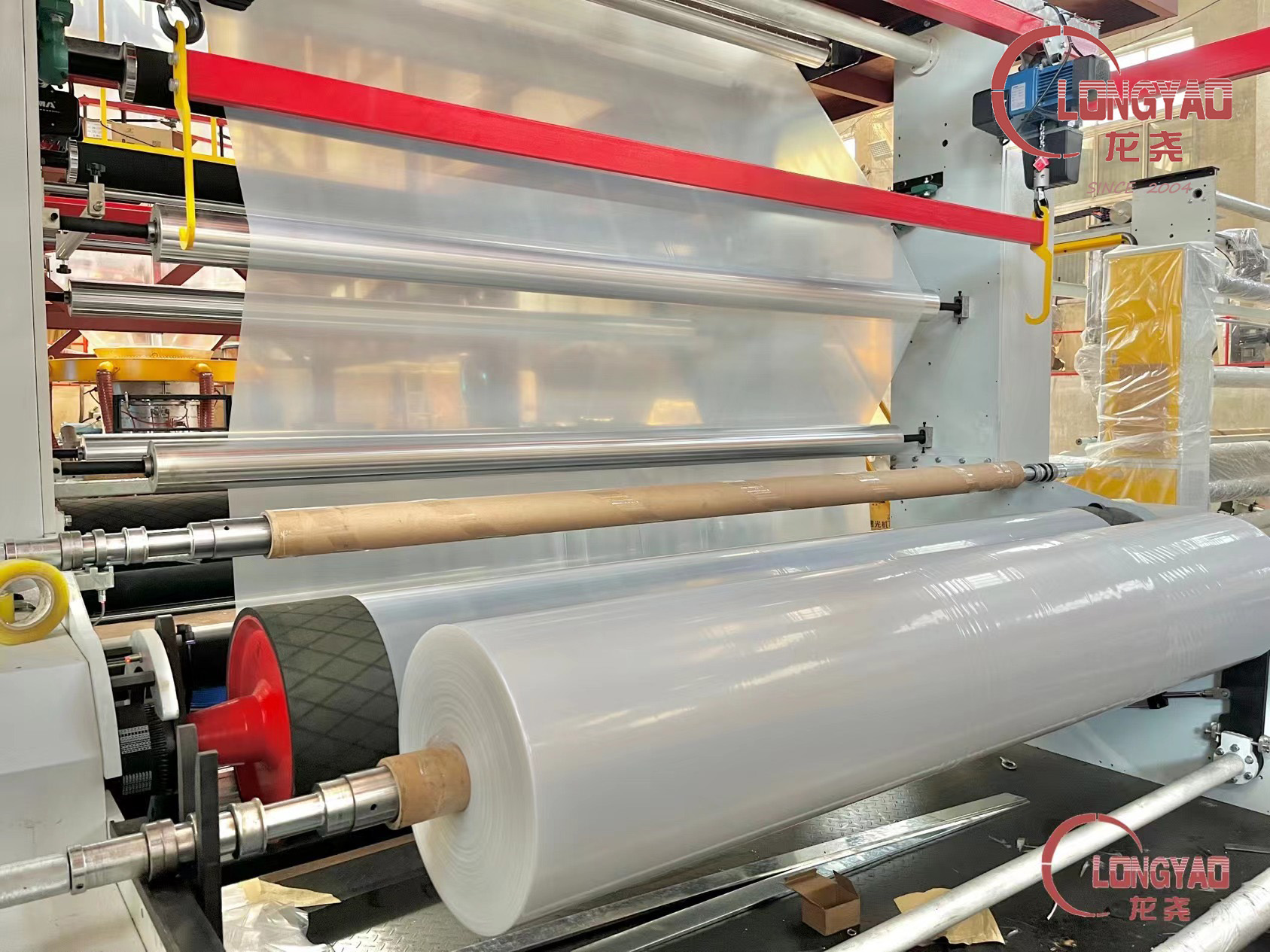

ABA Three Layer High Speed Plastic Film Blowing Machine

Features

We all know that Single Layer Plastic Film Blowing Machine has only one extruder, then, AB Two-layer Co-extrusion Blown Film Machine has two extruders; ABA Three Layer High Speed Plastic Film Blowing Machine is even more different Yes, although he only has two extruders, its flow channel is three-layer, which is a three-layer spiral mandrel type head structure. This is what makes it special. Let's explore why many users choose ABA Three Layer High Speed Plastic Film Blowing Machine.

The reasons are as follows:

1. Cost savings

2. Although one extruder is missing, it does not affect their film quality;

3. It is still three-layer co-extrusion, and the film produced is more tensile than single-layer and two-layer blown film machine equipment.

Specification

ABA | MODEL | SJM-Z45X45-800MM | SJM-Z50X50-1000MM | SJM-Z55X55-1200MM | SJM-Z65X65-1400MM |

BASIC PARAMETER | Suitable materials | HDPE,,LLDPE,Caco3 | |||

Film width | 400mm-600mm | 600mm-800mm | 500mm-1100mm | 700mm-1300mm | |

Film thickness | 0.02-0.10mm | ||||

Max output | 50-70kg/h | 70-100kg/h | 90-150kg/h | 100-180kg/h | |

Extruder | Screw diameter | Φ45;Φ45 | Φ50;Φ50 | Φ55;Φ55 | Φ65;Φ65 |

Barrel outside diameter | Φ120;Φ120 | Φ120;Φ120 | Φ120;Φ120 | Φ150;Φ150 | |

L/D | 30:1 or 32:1 | ||||

Main motor power | 18.5KW X2 | 22KW X2 | 37KW X2 | 45KW X2 | |

Gear box type | 146X2 | 173X2 | 180X2 | 225X2 | |

Die head diameter | Φ50m;Φ70m

| Φ60m;Φ70m

| Φ80m;Φ100m

| Φ100m;Φ150m

| |

Air ring blower | 5.5KW | 5.5KW | 7.5KW | 11KW | |

Filter type | Standard screw control or Manual filter screen changer | ||||

Take up unit | Roller width | 800mm | 1000mm | 1200mm | 1400mm |

Take-up speed | 5-100m/min | 5-100m/min | 5-100m/min | 5-100m/min | |

Take-up motor | 1.5kw | 1.5kw | 1.5kw | 1.5kw | |

Rotary type | Rotary die head | Rotary die head | Rotary die head | Rotary die head | |

Winder unit | Winder type | automatic back to back winder /single surface friction winder/Central winder | |||

Winding motor | 1.5kw | 1.5kw | 1.5kw | 2.2kw | |

Winding speed | 5-100m/min | 5-100m/min | 5-100m/min | 5-100m/min | |

Control unit | Electrical part | ABB/Schneider/Siemens | |||

inverter | ABB/AILAND/EURA/Yaskawa/Inovance/Slanvert/Delta (according to customer requirements) | ||||

Product Detail

Product Description

This ABA Three Layer High Speed Plastic Film Blowing Machine has two main machines, two brand reducers, and the machine head is a three-layer spiral mandrel structure, which feeds raw material particles into the hopper according to the user's own needs. The three-layer spiral mandrel type machine head cannot be seen from the outside to see any difference, but the internal structural engineer will draw a drawing for the user to see.