3 Layer HDPE Complex Base Material Film Blowing Machine

Features

The composite film produced by HDPE complex base material film blowing machine is a polymer material composed of two or more layers of films of different materials, and is mainly used for packaging.

The structure of the composite film of the multi-layer co-extrusion blown film machine depends on the functional requirements of the film.

ABC PE Foam complex film blowing machine has three layers. In the barrier layer, two different polymers are used to replace a single polymer, which can significantly improve the barrier properties of the film.

Specification

ABC | MODEL | SJM-Z55X65X55-1800MM | SJM-Z65X75X65-2000MM |

BASIC PARAMETER | Suitable materials | LDPE,LLDPE,mLLDPE,HDPE | |

Film width | 1000mm-1600mm | 1200mm-1800mm | |

Film thickness | 0.02-0.15mm | ||

Max output | 160-240kg/h | 200-260kg/h | |

Extruder | Screw diameter | Φ55;Φ65;Φ55 | Φ65;Φ75;Φ65 |

Barrel outside diameter | Φ120;Φ120;Φ150 | Φ150x3 | |

L/D | 30:1/32:1 | ||

Main motor power | 37KW X2;45KW | 45KWx2;55KWX1 | |

Gear box type | 180X2;225X1 | 225X2;250X1 | |

Die head diameter | Φ400mm

| Φ450mm

| |

Air ring blower | 18.5KW | 22KW | |

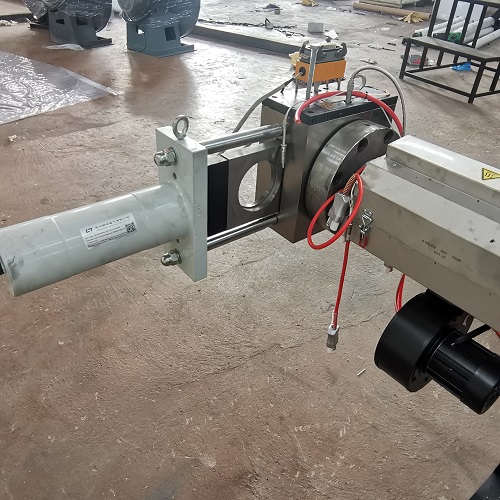

Filter type | Standard screw control /Hydraulic filter screen changer | ||

Take up unit | Roller width | 1800mm | 2000mm |

Take-up speed | 5-100m/min | 5-100m/min | |

Take-up motor | 1.5kw | 2.2kw | |

Rotary type | Horizontal type/oscillating rotating | Horizontal type/oscillating rotating | |

Winding unit | Winder type | automatic back to back friction winder /Manual back to back friction winder | |

Automatic tension system | Tension sensor | ||

Winding motor | 1.5kw | 2.2kw | |

Winding speed | 5-100m/min | 5-100m/min | |

Control unit | Electrical part | ABB/Schneider/Siemens | |

inverter | ABB/AILAND/EURA/Yaskawa/Inovance/Slanvert/Delta (according to customer requirements) | ||

Optional | EPC system / Oscillating rotating system / IBC system /automatic winder etc. | ||

Product Detail

3 Layer HDPE Complex Base Material Film Blowing Machine description

1.HDPE Complex Base Material Film is a type of plastic film made from high-density polyethylene (HDPE) resin. This film is produced using a complex base material film blowing process, which involves extruding multiple layers of HDPE resin through 3 Layer HDPE Complex Base Material Film Blowing Machine.

2.The complex base material film blowing process allows for the production of films with multiple layers, each with its own unique properties. For example, the outer layer of the HDPE film blowing machine may be designed to provide superior strength and durability, while the inner layers may be designed to provide excellent barrier properties and puncture resistance.

3.HDPE Complex Base Material Film is widely used in various industries for a range of applications. In the food industry, it is used for packaging food products such as fresh produce, meat, and dairy products. In the healthcare industry, it is used for packaging medical equipment and supplies. It is also used in the agriculture industry for crop protection and in the construction industry for protective wrapping and insulation.

4.Some of the key features and benefits of HDPE Complex Base Material Film include excellent mechanical properties such as strength and toughness, good chemical resistance, and the ability to be easily recycled. Additionally, the film is lightweight, flexible, and cost-effective, making it a popular choice for many different applications.