HDPE Embossed Flat Bags Film Blowing Machine

Features

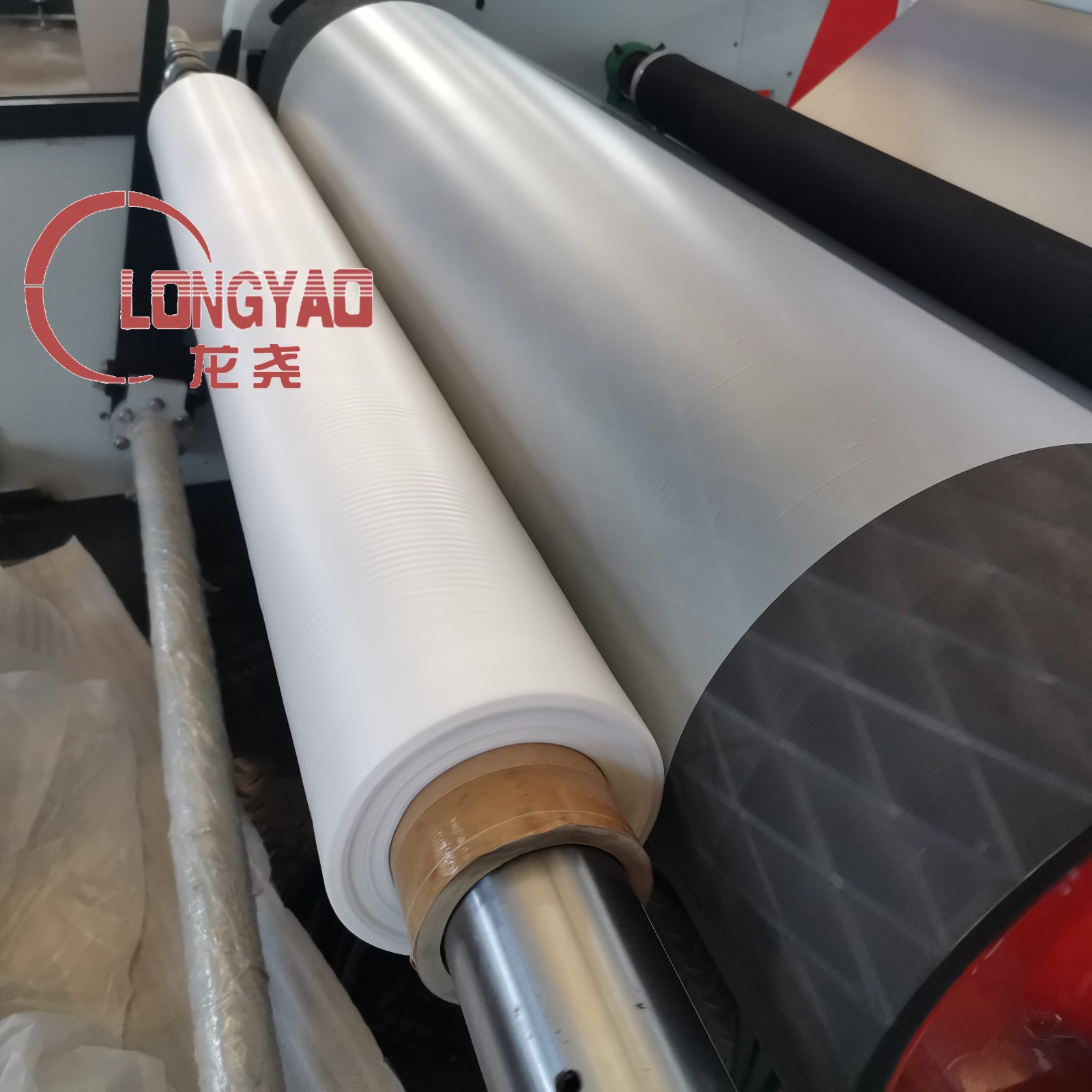

An HDPE embossed flat bags film blowing machine can be equipped with an embossing roller to create a textured or patterned surface on the film.

The embossing roller is typically made of materials such as rubber or steel and can be customized to create different patterns or textures on the film.

The embossing process involves passing the film through the nip of the embossing roller, which applies pressure to the film to create the desired texture or pattern.

The embossed film can then be used to produce flat bags with a textured surface that can provide additional grip or visual appeal.

Embossing can also be used to create branding or logos on the film.

HDPE Embossed Flat Bags Film Blowing Machine Specification

| MODEL | SJM-Z45-650 | SJM-Z50-850 | SJM-Z55-1100 | SJM-Z65-1400 |

BASIC PARAMETER | Suitable materials | HDPE,LDPE,LLDPE,MLLDPE | |||

Film width | 300mm-500mm | 400mm-700mm | 600mm-1000mm | 1000mm-1300mm | |

Film thickness | HD;0.008mm-0.05mm;LD:0.02-0.10mm | ||||

Max output | 35-60kg/h | 40-70kg/h | 60-100kg/h | 70-120kg/h | |

Extruder | Screw diameter | Φ45 | Φ50 | Φ55 | Φ65 |

Barrel outside diameter | Φ110 | Φ110 | Φ120 | Φ150 | |

L/D | 30:1 or 32:1 | ||||

Main motor power | 18.5KW | 22KW | 30KW | 37KW | |

Gear box type | 146 | 173 | 180 | 225 | |

Die head diameter | HDφ50m LDΦ120mm | HDΦ60mm LDΦ160mm | HDΦ80mm LDΦ200mm | HDΦ100mm LDΦ250mm | |

Air ring blower | 4KW | 4KW | 5.5KW | 7.5KW | |

Filter type | Standard screw control or Manual filter screen changer | ||||

Take up unit | Roller width | 650mm | 850mm | 1100mm | 1400mm |

Take-up speed | 5-100m/min | 5-100m/min | 5-100m/min | 5-100m/min | |

Take-up motor | 1.5kw | 1.5kw | 1.5kw | 2.2kw | |

Rotary type | Rotary die head | Rotary die head | Rotary die head | Rotary die head | |

Winder unit | Winder type | automatic back to back winder /single surface friction winder/Central winder | |||

Winding motor | 1.5kw | 1.5kw | 1.5kw | 1.5kw | |

Winding speed | 5-100m/min | 5-100m/min | 5-100m/min | 5-100m/min | |

Control unit | Electrical part | ABB/Schneider/Siemens | |||

inverter | ABB/AILAND/EURA/Yaskawa/Inovance/Slanvert/Delta (according to customer requirements) | ||||

HDPE Embossed Flat Bags Film Blowing Machine Description

1.HDPE Embossed Flat Bags Film Blowing Machine is a type of equipment used in the manufacturing of embossed flat bags made from High Density Polyethylene (HDPE) plastic material.

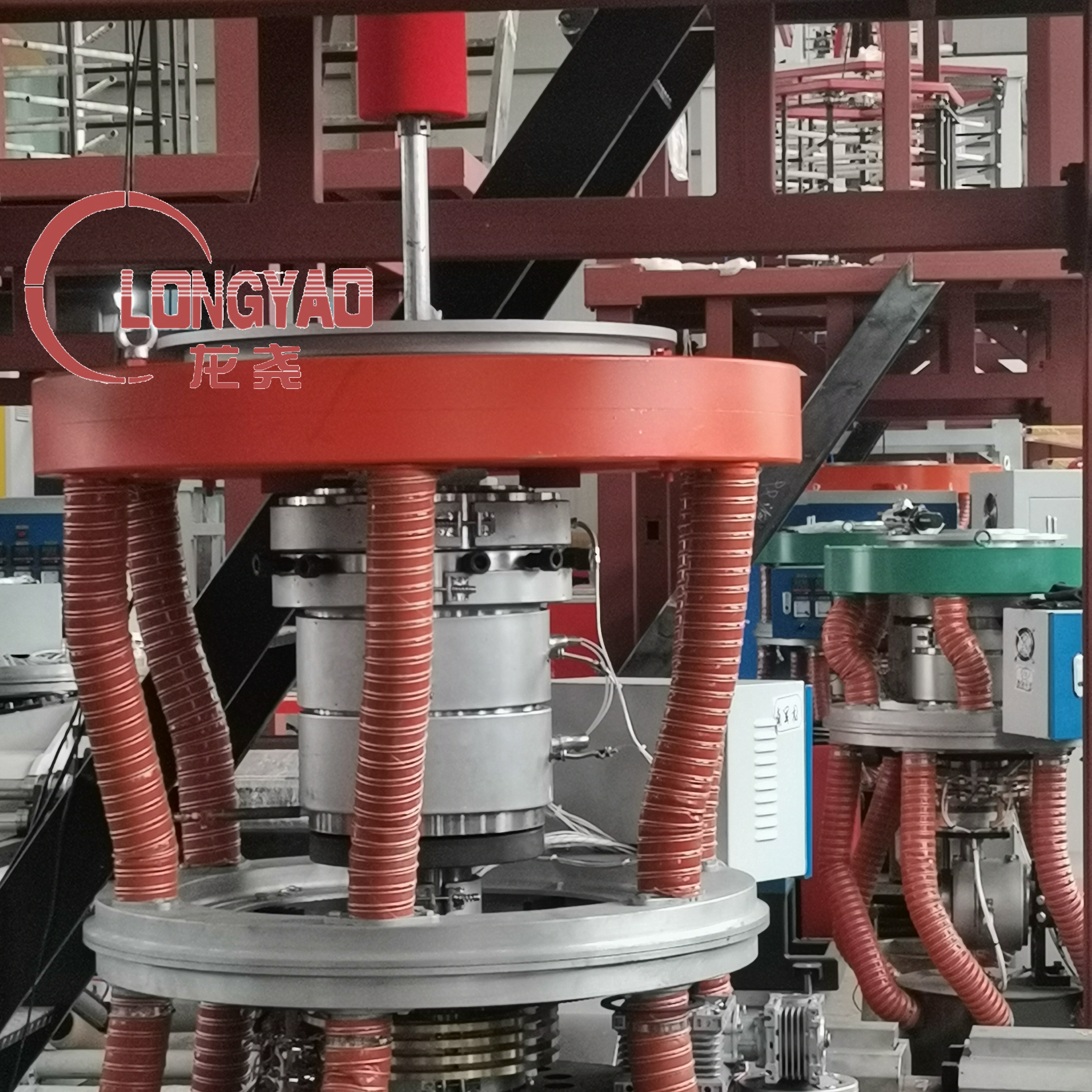

2.The process involves melting HDPE resin pellets and extruding them through a circular die head to form a continuous tube of plastic film. This tube is then guided through a set of nip rollers, which flatten and cool the film. During this process, the film is also embossed with a pattern or design that provides a better grip and reduces slippage.

3.The machine typically includes a number of components, such as an extruder, a die head, a cooling system, a nip roller assembly, a winder, and a control panel. The extruder is responsible for melting and extruding the HDPE resin, while the die head shapes the plastic into a tube. The cooling system rapidly cools the film, allowing it to be easily handled and wound onto a roll by the winder. The control panel allows operators to adjust various machine settings, such as speed and temperature, to ensure optimal performance and consistent production.

4.the HDPE Embossed Flat Bags Film Blowing Machine is a key piece of equipment in the production of high-quality embossed flat bags made from HDPE plastic.

HDPE Embossed Flat Bags Film Blowing Machine Detail