AB Two-layer Co-extrusion Blown Film Machine

Features

1. AB Two-layer Co-extrusion Blown Film Machine is composed of two extruders;

2. The blown film machine uses multiple extruders to form a new type of functional film by extruding through a special head in a molten state.

3. The difference from the single-layer film blowing machine used before is that it only needs one process to make a multi-layer and multi-functional composite film, thus avoiding multiple composite production processes and reducing production energy consumption and Material costs.

4. The AB head of the AB co-extrusion film blowing machine can save about 30% of the production cost compared with other composite processes.

AB Two-layer Co-extrusion Blown Film Machine Specification

ABA | MODEL | SJM-Z45X45-800MM | SJM-Z50X50-1000MM | SJM-Z55X55-1200MM | SJM-Z65X65-1400MM |

BASIC PARAMETER | Suitable materials | HDPE,,LLDPE,Caco3 | |||

Film width | 400mm-600mm | 600mm-800mm | 500mm-1100mm | 700mm-1300mm | |

Film thickness | 0.02-0.10mm | ||||

Max output | 50-70kg/h | 70-100kg/h | 90-150kg/h | 100-180kg/h | |

Extruder | Screw diameter | Φ45;Φ45 | Φ50;Φ50 | Φ55;Φ55 | Φ65;Φ65 |

Barrel outside diameter | Φ120;Φ120 | Φ120;Φ120 | Φ120;Φ120 | Φ150;Φ150 | |

L/D | 30:1 or 32:1 | ||||

Main motor power | 18.5KW X2 | 22KW X2 | 37KW X2 | 45KW X2 | |

Gear box type | 146X2 | 173X2 | 180X2 | 225X2 | |

Die head diameter | Φ50m;Φ70m

| Φ60m;Φ70m

| Φ80m;Φ100m

| Φ100m;Φ150m

| |

Air ring blower | 5.5KW | 5.5KW | 7.5KW | 11KW | |

Filter type | Standard screw control or Manual filter screen changer | ||||

Take up unit | Roller width | 800mm | 1000mm | 1200mm | 1400mm |

Take-up speed | 5-100m/min | 5-100m/min | 5-100m/min | 5-100m/min | |

Take-up motor | 1.5kw | 1.5kw | 1.5kw | 1.5kw | |

Rotary type | Rotary die head | Rotary die head | Rotary die head | Rotary die head | |

Winder unit | Winder type | automatic back to back winder /single surface friction winder/Central winder | |||

Winding motor | 1.5kw | 1.5kw | 1.5kw | 2.2kw | |

Winding speed | 5-100m/min | 5-100m/min | 5-100m/min | 5-100m/min | |

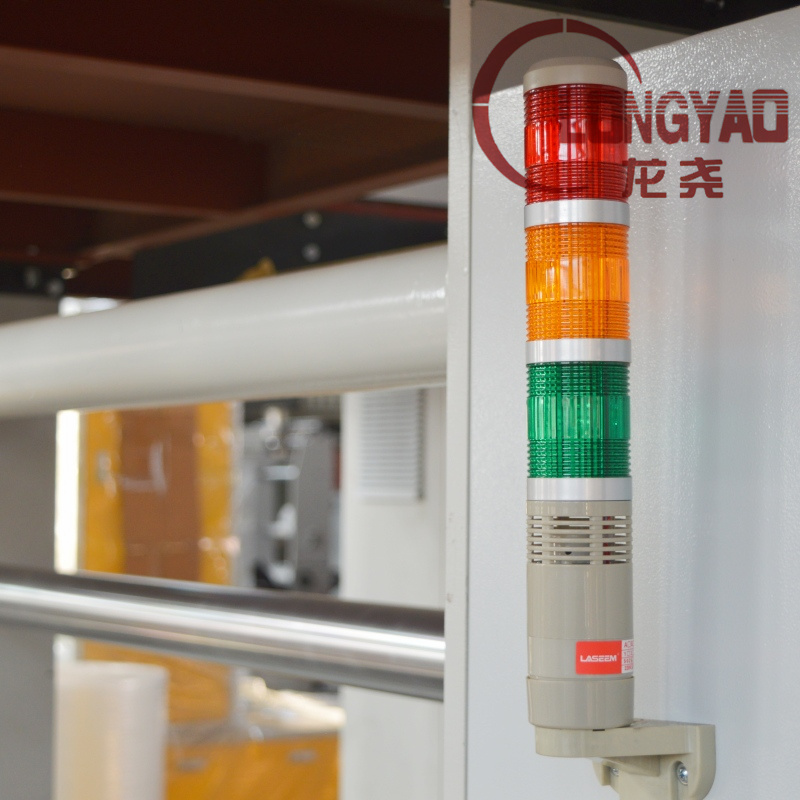

Control unit | Electrical part | ABB/Schneider/Siemens | |||

inverter | ABB/AILAND/EURA/Yaskawa/Inovance/Slanvert/Delta (according to customer requirements) | ||||

Product Detail

AB Two-layer Co-extrusion Blown Film Machine description

1. Our company has some excellent cases of AB Two-layer Co-extrusion Blown Film Machine, such as used to produce shrink film and industrial packaging, etc.

2. In addition, the delivery date of our film blowing machine equipment will be confirmed with the customer. Generally, the film blowing machine will be tested ten days in advance

3. What is special is that when testing the AB co-extrusion film blowing machine, it is of course better if the customer can come to the site. If the time and region do not allow, we can also arrange a video to see the test situation of the PE Blown Film machine on site.